Chemical Resistant Coating

Zeraus' chemical resistant coating flooring systems are designed to give outstanding resistance to damage resulting from acids, oil, solvents and other harsh chemicals.

Chemical Resistant Product Line

ZeraDur N300CR (Formerly ZeraChem N)

This epoxy novolac system resists to a broad range of chemicals including 98% sulfuric acid as well as most solvents. It is especially suitable in areas subject to high concentrations of acids such as metal plating, chemical processing plants, storage areas, battery recycling plants, waste treatment facilities and secondary containment areas.

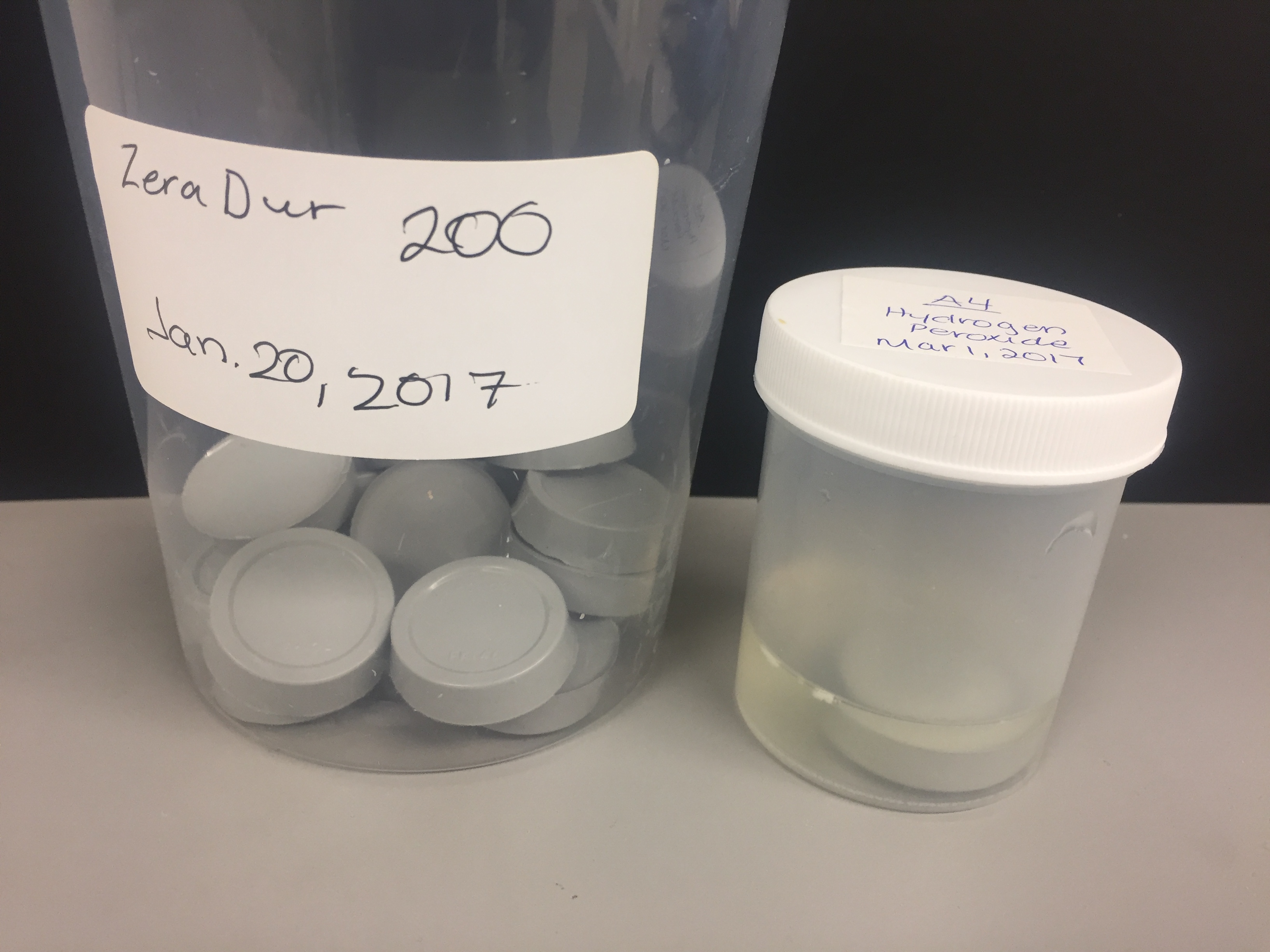

ZeraDur™ 200

This high-performance heavy duty 100% solids epoxy coating exhibits very good all-around resistance to alkalis, solvents, and most mineral acids. It combines excellent aesthetics, color stability, fast-setting and outstanding durability. It is designed for many applications including laboratories, pharmaceutical industries and steel manufacturing facilities.

ZeraClad™ V-100

It is a high performance two-component, 100% solids epoxy floor coating and wall coating that provides an aesthetically pleasing high gloss finish combined with very good chemical resistance. It is a highly durable coating and specially formulated based on a color stable cycloaliphatic amine hardener. ZeraClad V-100 is recommended as a wall coating for laboratories, swimming pool, shower rooms, locker-rooms, hospitals, warehouse facilities, food and meat packaging plants, breweries, recreational facilities, underwater fountains and pharmaceutical plants.

ZeraKlear™ CR

It is a 100% solids, two-component, clear epoxy coating that possesses very good all-around chemical resistance. It generates a hard-smooth attractive gloss finish with excellent mechanical strength and durability.

Chemical Resistant Charts

Chemical Resistance Charts for Flooring and Coatings

ASTM C722 Chemical Resistance Test: 7 Days Full Immersion @ 23°C/50% RH (7 Days Full Cure)

ACIDS

| Chemicals | Conc. | ZeraDur 200 | ZeraDur 300 | ZeraKlear CR | ZeraClad V-100 | ZeraBrite SA | ZeraSpart 100 |

| Acetic Acid | 10% | E | E | E | E | E | E |

| 20% | E | E | E | E | E | E | |

| 40% | F | E | F | F | F | F | |

| glac. | F | F | F | F | F | F | |

| Battery Acid | E | E | E | E | |||

| Benzoic Acid | E | E | E | E | |||

| Boric Acid | E | E | E | E | |||

| Citric Acid | 50% | E | E | E | E | ||

| Chromic Acid | 50% | E | E | E | E | ||

| Formic Acid | 10% | F | E | F | F | ||

| 20% | F | E | F | F | |||

| 50% | F | E | F | F | F | F | |

| Flourosilicic Acid | 10% | E | E | E | E | ||

| 35% | E | E | E | E | |||

| Glycolic Acid | 20% | E | E | E | E | ||

| 40% | F | F | F | F | |||

| 98% | F | F | F | F | |||

| Hydrochloric Acid | 20% | E | E | E | E | E | E |

| 36% | E | E | E | E | E | E | |

| Lactic Acid | 20% | E | E | E | F | ||

| 40% | E | E | E | F | |||

| 88% | E | S | E | F | S | S | |

| Nitric Acid | 20% | E | E | E | E | ||

| 40% | E | E | E | E | |||

| 60% | E | E | S | E | S | S | |

| 100% | F | F | F | F | |||

| Sulphamic Acid | 40% | E | E | E | E | E | E |

| Sulphuric Acid | 40% | E | E | E | E | E | E |

| 70% | E | E | E | E | E | E | |

| 98% | F | E | F | F | |||

| Phosphoric Acid | 35% | E | E | E | E | E | E |

| 75% | E | E | E | E | E | E | |

| Tartaric Acid | 0.5 | E | E | E | E |

RATING LEGEND

E - Excellent (no effect), slight loss of gloss

G - Good (only slight discoloration or staining, otherwise no effect)

S - Satisfactory (slight softening or blistering but film integrity intact)

F - Fail, not recommended (severe attack, swelling, sample destroyed)

Note: some discoloration might not be acceptable for customer in certain applications. Please check before making recommendation.

RATING BY RECOMMENDATION

E&G - For Immersion

S - For splash and spill only

F - Not recommended

SOLVENTS

| Chemicals | ZeraDur 200 | ZeraDur 300 | ZeraKlear CR | ZeraClad V-100 | ZeraBrite SA | ZeraSpart 100 |

| Acetate, PM | E | E | E | E | F | F |

| Chlorine | E | E | E | E | F | F |

| Acetone | G | F | S | G | ||

| Benzyl Alcohol | G | F | S | E | F | F |

| Butanol | E | E | E | E | ||

| n.Butyl Acetate | E | E | E | E | ||

| Butyl Carbitol | E | E | E | E | F | F |

| Cyclohexanol | E | E | E | E | ||

| Dibasic Ester | E | E | E | E | ||

| D-Limonene | E | E | E | E | F | F |

| Ethanol | E | E | E | E | E | E |

| Ethyl Acetate | S | S | S | S | F | F |

| Furfural Alcohol | F | F | F | F | F | F |

| Isopropanol | E | E | E | E | S | S |

| Methanol | G | E | G | S | F | F |

| Methylene Chloride | F | F | F | F | F | F |

| Methyl Ethyl ketone (MEK) | G | F | F | F | F | F |

| Methyl Isobutyl Ketone (MIBK) | E | E | E | E | E | E |

| Methyl pyrrolidene | F | F | F | F | F | F |

| Mineral Spirits | E | E | E | E | ||

| Naphtha, H.F. | E | E | E | E | ||

| Oxol 100 | E | E | E | E | ||

| Tetrahydro Furfural Alcohol | F | F | F | F | F | F |

| Toluene | E | E | E | E | ||

| Trichloroethane | F | F | F | F | F | F |

| Varsol | E | E | E | E | ||

| Xylene | E | E | E | E | E | E |

RATING LEGEND

E - Excellent (no effect), slight loss of gloss

G - Good (only slight discoloration or staining, otherwise no effect)

S - Satisfactory (slight softening or blistering but film integrity intact)

F - Fail, not recommended (severe attack, swelling, sample destroyed)

Note: some discoloration might not be acceptable for customer in certain applications. Please check before making recommendation.

RATING BY RECOMMENDATION

E&G - For Immersion

S - For splash and spill only

F - Not recommended

BASES

| Chemicals | ZeraDur 200 | ZeraDur 300 | ZeraKlear CR | ZeraClad V-100 | ZeraBrite SA | ZeraSpart 100 |

| Ammonium Benzoate | E | E | E | E | E | E |

| Ammonium Hydroxide | E | E | E | E | E | E |

| Potassium Hydroxide | E | E | E | E | E | E |

| Potassium Hydroxide | E | E | E | E | E | E |

| Sodium Chloride | E | E | E | E | E | E |

| Sodium Hydroxide | E | E | E | E | E | E |

| Sodium Hydroxide | E | E | E | E | E | E |

| Sodium Hypochlorite | E | E | E | E | E | E |

| Trisodium Phosphate | E | E | E | E | E | E |

| Zinc Oxide Solution | E | E | E | E | E | E |

| Zinc Sulphate | E | E | E | E | E | E |

| Calcium Chloride | E | E | E | E | E | E |

| Sodium Sulphide | E | E | E | E | E | E |

RATING LEGEND

E - Excellent (no effect), slight loss of gloss

G - Good (only slight discoloration or staining, otherwise no effect)

S - Satisfactory (slight softening or blistering but film integrity intact)

F - Fail, not recommended (severe attack, swelling, sample destroyed)

Note: some discoloration might not be acceptable for customer in certain applications. Please check before making recommendation.

RATING BY RECOMMENDATION

E&G - For Immersion

S - For splash and spill only

F - Not recommended

PETROLEUM PRODUCTS

| Chemicals | ZeraDur 200 | ZeraDur 300 | ZeraKlear CR | ZeraClad V-100 | ZeraBrite SA | ZeraSpart 100 |

| Brake Fluid | E | E | E | E | E | E |

| Diesel Fuel | E | E | E | E | E | E |

| Engine Oil (10 W30) | E | E | E | E | E | E |

| Esso Turbo Oil | E | E | E | E | E | E |

| Gasoline | E | E | E | E | E | E |

| Hydraulic Fluid | E | E | E | E | E | E |

| Jet Fuel | E | E | E | E | E | E |

| Skydrol | E | E | E | E | E | E |

| Brine | E | E | E | E | E | E |

| L-602 | E | E | E | E | E | E |

| Transformer Oil | E | E | E | E | E | E |

| Transmission Fluid | E | E | E | E | E | E |

| Turbo Fuel B | E | E | E | E | E | E |

RATING LEGEND

E - Excellent (no effect), slight loss of gloss

G - Good (only slight discoloration or staining, otherwise no effect)

S - Satisfactory (slight softening or blistering but film integrity intact)

F - Fail, not recommended (severe attack, swelling, sample destroyed)

Note: some discoloration might not be acceptable for customer in certain applications. Please check before making recommendation.

RATING BY RECOMMENDATION

E&G - For Immersion

S - For splash and spill only

F - Not recommended

CHEMICALS

| Chemicals | ZeraDur 200 | ZeraDur 300 | ZeraKlear CR | ZeraClad V-100 | ZeraBrite SA | ZeraSpart 100 |

| Diamines | E | E | E | E | E | E |

| Ethylene Glycol | ||||||

| Ethyl Morpholine | E | E | E | E | E | E |

| Formaldehyde | E | E | E | E | E | E |

| Glycerin | E | E | E | E | E | E |

| Hydrazine Hydrate | E | E | E | E | E | E |

| Hydogen Peroxide (10%) | E | E | E | E | E | E |

| Hydogen Peroxide (30%) | S | S | S | F | F | F |

| Hydogen Peroxide (50%) | F | F | F | F | F | F |

| Pyridine | E | E | E | E | E | E |

| Styrene | E | E | E | E | E | E |

RATING LEGEND

E - Excellent (no effect), slight loss of gloss

G - Good (only slight discoloration or staining, otherwise no effect)

S - Satisfactory (slight softening or blistering but film integrity intact)

F - Fail, not recommended (severe attack, swelling, sample destroyed)

Note: some discoloration might not be acceptable for customer in certain applications. Please check before making recommendation.

RATING BY RECOMMENDATION

E&G - For Immersion

S - For splash and spill only

F - Not recommended

FOOD & MISC.

| Chemicals | ZeraDur 200 | ZeraDur 300 | ZeraKlear CR | ZeraClad V-100 | ZeraBrite SA | ZeraSpart 100 |

| Beer | E | E | E | E | E | E |

| Blood | E | E | E | E | E | E |

| Coffee | E | E | E | E | E | E |

| Coke | E | E | E | E | E | E |

| Cooking Oil | E | E | E | E | E | E |

| Honey | E | E | E | E | E | E |

| Hot Animal Fat | E | E | E | E | E | E |

| Javex | E | E | E | E | E | E |

| Ketchup | E | E | E | E | E | E |

| Lard | E | E | E | E | E | E |

| Margarine | E | E | E | E | E | E |

| Milk | E | E | E | E | E | E |

| Mustard | E | E | E | E | E | E |

| Pine Oil | E | E | E | E | E | E |

| Tea | E | E | E | E | E | E |

| Acidic Waste Water @180F | F | F | F | S | F | F |

| Urine (Animal) | E | E | E | E | E | E |

RATING LEGEND

E - Excellent (no effect), slight loss of gloss

G - Good (only slight discoloration or staining, otherwise no effect)

S - Satisfactory (slight softening or blistering but film integrity intact)

F - Fail, not recommended (severe attack, swelling, sample destroyed)

Note: some discoloration might not be acceptable for customer in certain applications. Please check before making recommendation.

RATING BY RECOMMENDATION

E&G - For Immersion

S - For splash and spill only

F - Not recommended

CHEMICAL RESISTANCE OF WATERBORNE COATINGS

ASTM D 1308 – Covered Spot Test, 24hrs @ 23C

| Chemical | ZeraTuf W-104 | ZeraTuf W-104 with Crosslinker | ZeraTuf W-104 Grey |

| Baking Soda | No Effect | No Effect | No Effect |

| Sugar | No Effect | No Effect | No Effect |

| Sulphuric Acid (10%) | No Effect | No Effect | Stained |

| Chlorine | No Effect | No Effect | No Effect |

| Lactic Acid (10%) | Stained | Stained | Stained |

| Colorax (50%) | No Effect | No Effect | No Effect |

| Windex | No Effect | No Effect | No Effect |

| Coffee | Stained | Stained | Stained |

| Ethanol (50%) | Stained | Stained | No Effect |

| CLR | No Effect | No Effect | Stained |

| White Wine | No Effect | No Effect | No Effect |

| Red Wine | Stained | Stained | Stained |

| Vinegar | No Effect | No Effect | No Effect |

| Tea | No Effect | No Effect | Stained |

| Milk | No Effect | No Effect | No Effect |

| Ketchup | No Effect | No Effect | Stained |

| Mustard | Stained | Stained | Stained |

| Cooking Oil | No Effect | No Effect | No Effect |

| Leather Cleaner | No Effect | No Effect | No Effect |

| Windsheild Washer Fluid | No Effect | No Effect | No Effect |

NOTE: The information contained herein is given in good faith to be used as a guide for product selection. Since operating conditions are beyond our control, customers must ensure that the product is suitable for the purpose in which it is intended. All information contained in this Chemical Resistance Chart is to be used as a guide and is subject to change without notice.